Summary

The stud pump is that one kind of one stud type is

lost the stud bush ( calling the stator ) that fortune pump and

stud ( calling the rotor ) and interior surface that its major work

parts are partiality spirochaetas assume the bifilar helix face .

His work principle is when being moving when the electromotor

drives the pump axle , and on the one hand the stud winds the axis

of itself and revolves , on the other hand its again surface roll

along the bush , so forming the close cavity room of pump . The

stud is one week per revolution , and liquid in the close

cavity pushes on forward a pitch . Along with the continuous

transmission of stud , the shape method of liquid with the spiral

is pressed to another close cavity from a close cavity , and

finally crowds out the pump aspect.

The stud pump is the machinery of one kind of new

transport liquid , and possesses that the structure is simple and

work is safe and reliable and use to keep in repair convenient and

goes out the merits such as liquid is continuously even and

pressure is stable etc . The dense thick liquid pump of my unit

production contacts altogether the metal part that the thing is

expected all chooses the high quality not to become

rusty the acidproof steel is made , axle material 2cr13 lines and

tin uses nonpoisonous tasteless rubber and work temperature 100 ℃s

attainability , available in the transport foodstuff thick liquids

and the viscosity 10000 moors this calorie of contains second

solid anything small and roundish or glue piece the solution

thick liquid , the corrosiveness medium of suspension liquid .

Extensively in the Ministry of Industry such as foodstuff ,

metallurgy , building , pharmacy and chemical industry etc the

doors Please paying attention to : The medium difference that the

stud pump uses should use the different rubber .

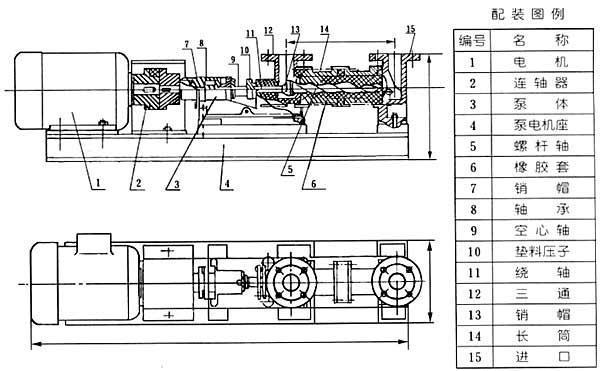

浓浆泵产品结构示意图

|

1

|

弯头接管

|

5

|

三通泵体

|

9

|

空心泵轴

|

|

2

|

直筒

|

6

|

石棉填料

|

10

|

泵座

|

|

3

|

橡胶管

|

7

|

填料压盖

|

11

|

销轴销帽

|

|

4

|

螺杆泵

|

8

|

绕轴

|

12

|

联轴器

|

|

型 号

|

理论流量

(m3/h) |

流量

( T/时) |

扬程

(m) |

吸程

(m) |

进出口径

|

转速

(r/min) |

配用电机

(K/w) |

工作压力

(kg/cm2) |

|

老型I-1B1寸

|

1.8

|

1.1

|

30

|

2

|

25

|

960

|

2.2

|

3

|

|

I-1B1寸

|

2.39

|

1.5

|

50

|

2

|

25

|

960

|

1.1

|

5

|

|

老型I-1B1.5寸

|

4.8

|

3

|

80

|

2

|

40

|

960

|

3

|

8

|

|

I-1B1.5寸

|

5.2

|

3.2

|

80

|

3

|

40

|

960

|

2.2

|

8

|

|

I-1B2寸

|

8.85

|

5.6

|

80

|

3

|

50

|

960

|

3

|

8

|

|

I-1B2.5寸

|

10.6

|

6.5

|

60

|

3

|

65

|

960

|

3

|

6

|

|

老型I-1B3寸

|

15

|

10

|

60

|

3

|

75

|

960

|

7.5

|

6

|

|

I-1B3寸

|

18.1

|

12

|

60

|

3

|

75

|

960

|

5.5

|

6

|

|

I-1B4寸

|

24

|

16

|

60

|

3

|

100

|

960

|

7.5

|

6

|

|

I-1B5寸

|

36

|

25

|

60

|

3

|

125

|

960

|

11

|

6

|

|

老型I-1B5寸

|

27

|

19

|

60

|

3

|

125

|

960

|

11

|

6

|

|

I-1B6寸

|

38

|

30

|

60

|

3

|

150

|

960

|

15

|

6

|

凯美泵业公司自螺杆泵选型须知:

一、浓浆泵产品名称与型号,浓浆泵管道口径,浓浆泵使用扬程(m),浓浆泵电机功率(KW),浓浆泵电机转速(r/min),浓浆泵电压〔V〕,浓浆泵使用的吸程(m),浓浆泵使用的介质名称、比重、粘度、腐蚀性、毒性

二、若已经由设计单位选定我公司的浓浆泵型号,请按浓浆泵型号直接向凯美泵业公司营销部订购。

三、请尽量提供详细的产品使用要求,以便我们选型的正确性,提高使用的**高效率。

感谢您访问凯美泵业的网站【//www.yjkmb.com/】,如有任何疑问.您可以致电0577-67958225,我们会用心做好每一件事情。

【注重细节,注重品质,凯美水泵】

Tel:

Tel:

Tel:

Tel: