一、PQ940F电动偏心半球阀特点:

1、解决了工业生产中的浆状、混流液体、灰尘等介质在管道输送中沉淀、易结垢、阻塞,使阀门关不严等问题。

2、开关轻便,开启时球与壳体脱离,无任何接触,启动扭矩小,转动灵活。关闭时,半球与阀座的挤切作用能除去密封面上的污物,使阀门顺利启闭,安全系数高,密封性能好。

3、密封面的偏心结构,使球面能自动补偿磨损,能保持阀门的密封,使用寿命长。

4、该阀门T型是属于耐磨硬密封球阀,它的密封副材料是特殊的,密封面要经过特殊耐磨处理。处理后表面达到HRC65-72度,故阀门的耐磨性能特别好。

5、阀门表面油漆,有常温和高温两种。高温用耐温600℃的进口漆,喷涂后,高温使用不烧漆、炭化、焦化现象。不变色。

二、PQ940F电动偏心半球阀主要性能参数及执行标准:

|

公称压力MPa |

1.0 |

1.6 |

2.5 |

4.0 |

|

阀门强度试验压力MPa |

1.5 |

2.4 |

3.8 |

6.0 |

|

阀门密封试验压力MPa |

1.1 |

1.8 |

2.8 |

4.5 |

|

适用温度℃ |

≤425℃ ≤325℃常温 |

|||

|

主要材质 |

||||

|

适用介质 |

煤粉、煤灰、含尘、气体 |

|||

|

法兰标准 |

JB/T82.1-94 |

|||

|

阀门结构长度标准 |

GB12221-89 |

|||

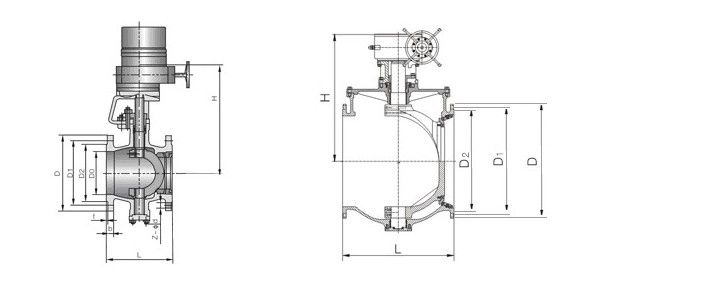

三、PQ940F电动偏心半球阀主要外形和连接尺寸:

|

公称压力 PN (MPa) |

公称通径 DN |

尺 寸(mm) |

||||||||

|

L |

D 系列1/系列2 |

D1 |

D2 |

D6 |

b |

f |

Z-φd |

|||

|

mm |

in |

法兰 |

||||||||

|

0.6 |

40 |

- |

125 |

130 |

100 |

80 |

- |

16 |

3 |

4-14 |

|

50 |

- |

140 |

140 |

110 |

90 |

- |

16 |

3 |

4-14 |

|

|

65 |

- |

190 |

160 |

130 |

110 |

- |

16 |

3 |

4-14 |

|

|

80 |

- |

178 |

190/185 |

150 |

125 |

- |

18 |

3 |

4-18 |

|

|

100 |

- |

200 |

210/205 |

170 |

145 |

- |

18 |

3 |

4-18 |

|

|

125 |

- |

254 |

240/235 |

200 |

175 |

- |

20 |

3 |

8-18 |

|

|

150 |

- |

267 |

265/260 |

225 |

200 |

- |

20 |

3 |

8-18 |

|

|

200 |

- |

292 |

320/315 |

280 |

255 |

- |

22 |

3 |

8-18 |

|

|

250 |

- |

330 |

375/370 |

335 |

310 |

- |

24 |

3 |

12-18 |

|

|

300 |

- |

390 |

440/435 |

395 |

362 |

- |

24 |

4 |

12-23 |

|

|

350 |

- |

430 |

490/485 |

445 |

412 |

- |

26 |

4 |

12-23 |

|

|

400 |

- |

530 |

540/535 |

495 |

465 |

- |

28 |

4 |

16-23 |

|

|

450 |

- |

580 |

595/590 |

550 |

518 |

- |

28 |

4 |

16-23 |

|

|

500 |

- |

630 |

645/640 |

600 |

568 |

- |

30 |

4 |

16-23 |

|

|

600 |

- |

800 |

755 |

705 |

670 |

- |

30 |

5 |

20-26/25 |

|

|

1.0 |

40 |

- |

125 |

145 |

110 |

85 |

- |

16 |

3 |

4-18 |

|

50 |

- |

140 |

160 |

125 |

100 |

- |

16 |

3 |

4-18 |

|

|

65 |

- |

190 |

180 |

145 |

120 |

- |

18 |

3 |

4-18 |

|

|

80 |

- |

178 |

195 |

160 |

135 |

- |

20 |

3 |

4-18 |

|

|

100 |

- |

200 |

215 |

180 |

155 |

- |

20 |

3 |

8-18 |

|

|

125 |

- |

254 |

245 |

210 |

185 |

- |

22 |

3 |

8-18 |

|

|

150 |

- |

267 |

280 |

240 |

210 |

- |

24 |

3 |

8-23 |

|

|

200 |

- |

292 |

335 |

295 |

265 |

- |

24 |

3 |

8-23 |

|

|

250 |

- |

330 |

390 |

350 |

320 |

- |

26 |

3 |

12-23 |

|

|

300 |

- |

390 |

440 |

400 |

368 |

- |

26 |

4 |

12-23 |

|

|

350 |

- |

430 |

500 |

460 |

428 |

- |

28 |

4 |

16-23 |

|

|

400 |

- |

530 |

565 |

515 |

482 |

- |

28 |

4 |

16-25 |

|

|

450 |

- |

580 |

615 |

565 |

532 |

- |

30 |

4 |

20-25 |

|

|

500 |

- |

630 |

670 |

620 |

585 |

- |

30 |

4 |

20-25 |

|

|

600 |

- |

800 |

480 |

725 |

685 |

- |

34 |

5 |

20-30 |

|

|

700 |

- |

900 |

895 |

840 |

800 |

- |

38 |

5 |

24-30 |

|

|

800 |

- |

1000 |

1010 |

950 |

905 |

- |

42 |

5 |

24-34 |

|

|

1.6 |

40 |

- |

125 |

145 |

110 |

85 |

- |

16 |

3 |

4-18 |

|

50 |

- |

140 |

160 |

125 |

100 |

- |

16 |

3 |

4-18 |

|

|

65 |

- |

190 |

180 |

145 |

120 |

- |

18 |

3 |

4-18 |

|

|

80 |

- |

178 |

195 |

160 |

135 |

- |

20 |

3 |

8-18 |

|

|

100 |

- |

200 |

215 |

180 |

155 |

- |

20 |

3 |

8-18 |

|

|

125 |

- |

254 |

245 |

210 |

185 |

- |

22 |

3 |

8-18 |

|

|

150 |

- |

267 |

280 |

240 |

210 |

- |

24 |

3 |

8-23 |

|

|

200 |

- |

292 |

335 |

295 |

265 |

- |

26 |

3 |

12-23 |

|

|

250 |

- |

330 |

405 |

355 |

320 |

- |

30 |

3 |

12-25 |

|

|

300 |

- |

390 |

460 |

410 |

375 |

- |

30 |

4 |

12-25 |

|

|

350 |

- |

430 |

520 |

470 |

435 |

- |

34 |

4 |

16-25 |

|

|

400 |

- |

530 |

580 |

525 |

485 |

- |

36 |

4 |

16-30 |

|

|

450 |

- |

580 |

640 |

585 |

545 |

- |

40 |

4 |

20-30 |

|

|

500 |

- |

630 |

705 |

650 |

608 |

- |

44 |

4 |

20-34 |

|

|

600 |

- |

800 |

840 |

770 |

718 |

- |

48 |

5 |

20-41 |

|

|

700 |

- |

900 |

910 |

840 |

788 |

- |

50 |

5 |

24-41 |

|

|

800 |

- |

1000 |

1020 |

950 |

898 |

- |

52 |

5 |

24-41 |

|

|

2.5 |

40 |

- |

125 |

145 |

110 |

85 |

- |

18 |

3 |

4-18 |

|

50 |

- |

140 |

160 |

125 |

100 |

- |

20 |

3 |

4-18 |

|

|

65 |

- |

190 |

180 |

145 |

120 |

- |

22 |

3 |

8-18 |

|

|

80 |

- |

178 |

195 |

160 |

135 |

- |

22 |

3 |

8-18 |

|

|

100 |

- |

200 |

230 |

190 |

160 |

- |

24 |

3 |

8-23 |

|

|

125 |

- |

254 |

270 |

220 |

188 |

- |

28 |

3 |

8-25 |

|

|

150 |

- |

267 |

300 |

250 |

218 |

- |

30 |

3 |

8-25 |

|

|

200 |

- |

292 |

360 |

310 |

278 |

- |

34 |

3 |

12-25 |

|

|

250 |

- |

330 |

425 |

370 |

332 |

- |

36 |

3 |

12-30 |

|

|

300 |

- |

390 |

485 |

430 |

390 |

- |

40 |

4 |

16-30 |

|

|

350 |

- |

430 |

550 |

490 |

448 |

- |

44 |

4 |

16-34 |

|

|

400 |

- |

530 |

610 |

550 |

505 |

- |

48 |

4 |

16-34 |

|

|

450 |

- |

580 |

660 |

600 |

555 |

- |

50 |

4 |

20-34 |

|

|

500 |

- |

630 |

730 |

660 |

610 |

- |

52 |

4 |

20-41 |

|